STMicroelectronics

AMK Industrial Park,

Singapore

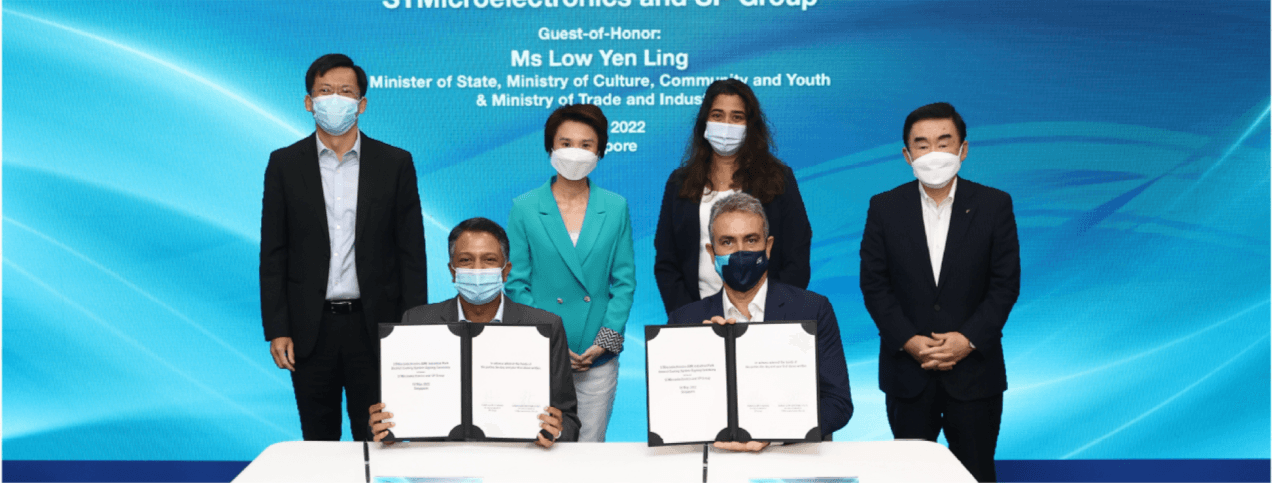

STMicroelectronics, one of the world’s largest semiconductor manufacturers, made a global commitment to become carbon neutral by 2027. With this target in mind, they were seeking ways to significantly reduce their carbon emissions – and fast. Since the manufacturing of semiconductor “wafers” demands massive process cooling capacity, seeking a more efficient cooling system was the perfect place to start. They selected SP Group (SP) to make the vision a reality. One unique factor was that the cooling system was required to cool both a manufacturing plant and office areas - in other words, spaces with very different cooling requirements.

In partnership with STMicroelectronics, SP will design, build, own, and operate Singapore's largest industrial District Cooling System. With a cooling capacity of up to 36,000 refrigeration tonnes, this project will be the largest district cooling system for an industrial development in Singapore when completed in 2025. This is ST’s first deployment of district cooling at a manufacturing facility globally - it will achieve 20 per cent savings in cooling-related electricity consumption every year, and at the same time, reduce ST’s carbon emissions by up to 120,000 tonnes per year.

"The cooling system in Singapore will be ST's first deployment of district cooling at manufacturing facility globally and is a strong statement of our commitment to our target to become carbon neutral globally by 2027"

- Rajita D'Souza, President of Human Resources and Corporate Social Responsibility at STMicroelectronics.

At a Glance

4,000 SQM

of freed up chiller plant space

120,000 tonnes per year

reduction in carbon emissions from the environment

36,000 RT

Cooling Capacity

20% savings

On Cooling-Related electricity consumption annually

Upon completion, ST will be able to repurpose more than 4,000sqm of freed up chiller plant space, allowing the integration of solar energy systems and other perfluorocarbons abatement equipment. Consequently, ST can reduce its carbon emissions by up to 120,000 tonnes per year, which is equivalent to removing nearly 110,000 cars off our roads.

Group CEO Stanley Huang said, “District Cooling is a key sustainable energy solution to empower a low-carbon future for cities, townships, and industrial parks. To enable the decarbonisation of Singapore’s industrial sector, we have customised this solution to help energy-intensive manufacturing developments such as STMicroelectronics’ TechnoPark reduce their energy consumption and carbon footprint in line with their sustainability strategies. With our full suite of sustainable energy solutions including solar and electric vehicle charging, we look forward to collaborating with ST to meet its net-zero targets.”

Have a business enquiry?

Interested to find out more how our integrated services can serve your business needs? Drop us an online enquiry, and our qualified professionals will reach out to you.